Thermo Fisher: ‘With the new tanks, our production process is safer and more flexible’

Gpi Pharma supplies four stainless steel tanks for the expansion of production capacity

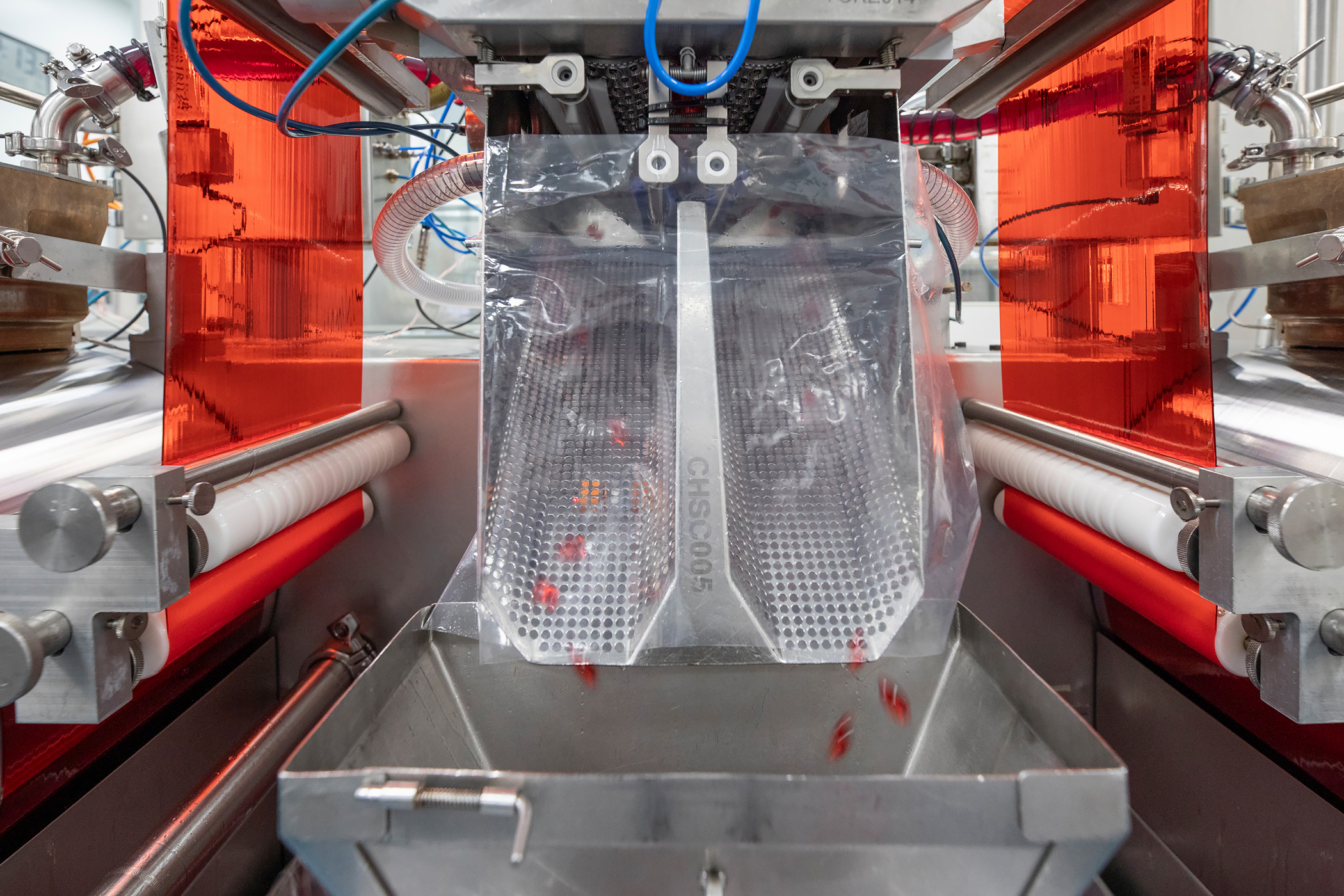

Thermo Fisher in Tilburg specializes in the development and production of pharmaceuticals in the form of softgels, soft gelatine capsules that provide a more comfortable experience for the end user. From the location in Tilburg, the medicines are delivered worldwide to various customers. To process a larger batch volume while simultaneously optimizing the internal workflow, an expansion of the storage capacity between process steps was necessary. Gpi Pharma supplied four stainless steel medicine tanks to support this expansion.

Maarten Meeuwis, Production Engineer at Thermo Fisher Tilburg, explains the origins of the request: ‘We use stainless steel tanks for the transport and temporary storage of the medicines before they are processed into the softgel capsules. As our mix tank capacity increased, the production volume also grew, which meant more medicine had to be stored and transported. This resulted in a capacity shortage in our stainless steel storage tanks.’

‘From drawings and calculations to material certificates and welding certificates, every step in the process is included in the documentation.’

Choosing Gpi

After previous successful collaborations, Thermo Fisher knew exactly what to expect from Gpi and therefore chose Gpi again for this project. The extensive and meticulous documentation provided with the stainless steel tanks played an important role in this decision. Maarten explains: ‘In previous projects, we were very satisfied with the documentation Gpi Pharma provided with the tanks. From drawings and calculations to material certificates and welding certificates, every step in the process is included in the documentation. For us, this is essential in order to meet the stringent requirements within the pharmaceutical industry.’

Choosing Gpi also brought another advantage for Thermo Fisher. Maarten explains: ‘Because Gpi had supplied similar stainless steel tanks in the past, we were able to use existing drawings as a starting point. That saved us a lot of additional work and valuable time. We wanted to put the new stainless steel tanks into use as quickly as possible.’

The assignment

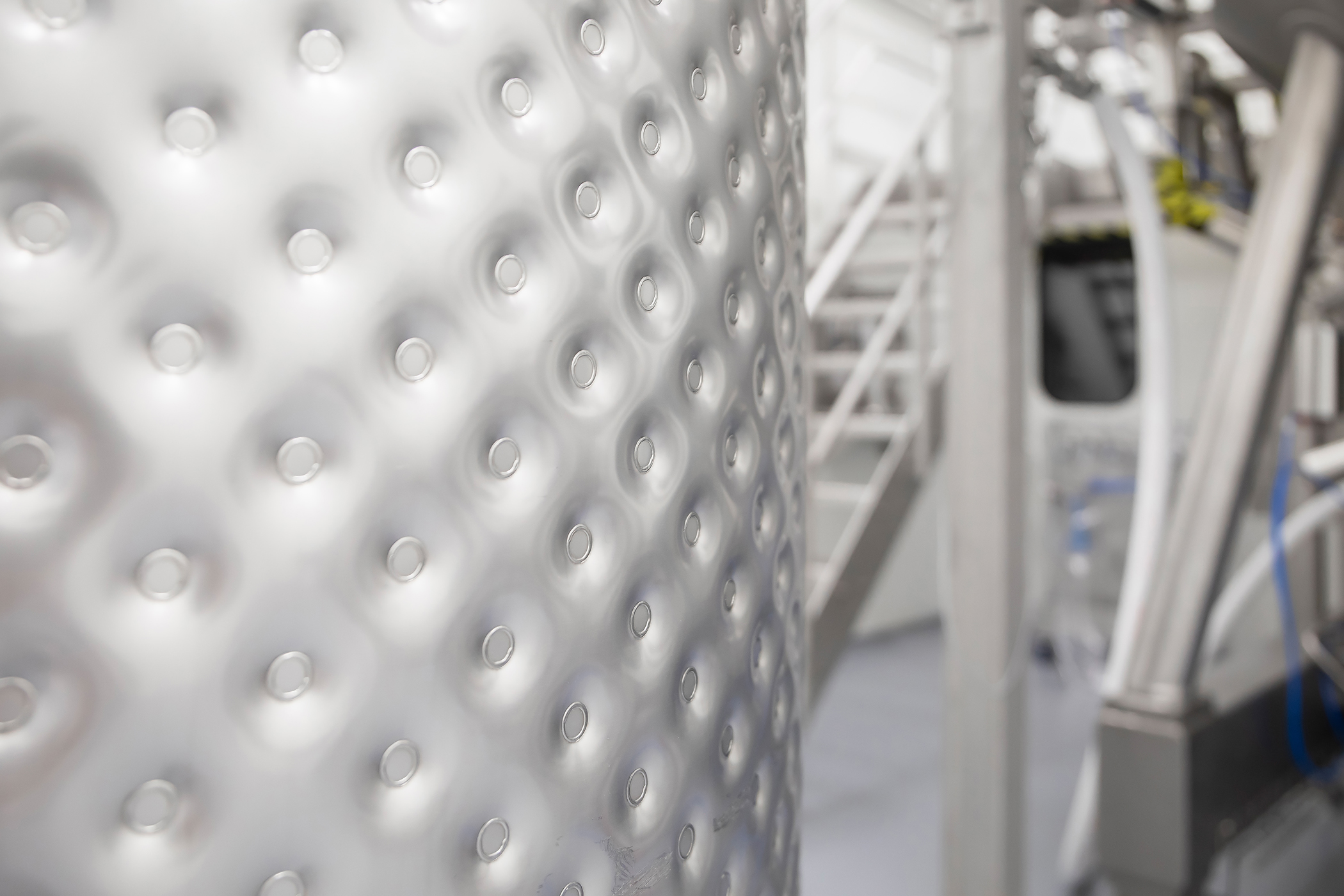

Gpi Pharma supplied four stainless steel medicine tanks with a working volume of 900 liters to Thermo Fisher in Tilburg. The tanks are made of high-quality 316L stainless steel to meet the highest quality and safety standards in the pharmaceutical industry. They are used for the storage and internal transport of the medicines between the preparation phase and the filling of the softgels. To further improve safety during internal transport, the top of the tank has been raised by 30 mm compared to the previous generation of tanks. This creates extra space for fluid movement during transport.

When handling pharmaceutical ingredients, accurate control of liquid temperatures is crucial. The stainless steel tanks are therefore equipped with a dimple plate heating jacket and an external agitator. Maarten explains: ‘The medicines must remain at the correct temperature throughout the process. That is why we chose a dimple plate heating jacket. In combination with an external agitator, this ensures a homogeneous temperature distribution of the medicines.’

The result

With the new tanks, Thermo Fisher is able to work safely and efficiently with a larger production volume. Maarten: ‘With the addition of the new stainless steel tanks, our storage capacity has increased, and the internal workflow between the various production steps has been optimized. Because existing designs could be used as a basis, the new tanks could be integrated directly into our production process without requiring any modifications.’

‘Gpi actively thinks along with our challenges.’

Collaboration and future outlook

Maarten also reflects positively on the collaboration and communication with Gpi: ‘Gpi actively thinks along with our challenges. Communication throughout the project was clear and pleasant, and there was room to further optimize the tanks where needed.’

The successful collaboration has received a great continuation this year. To prepare for a significant increase in demand starting January 2026, Thermo Fisher has placed an additional order for four 900-liter medicine tanks. The new stainless steel tanks will enable Thermo Fisher to continue meeting customer demand for softgels, even as demand continues to rise.